GOOD Vacuum extruder clay brick making machine

Vacuum extruder clay brick making machine for brick factory applies to clay, shale, coal gangue, fly ash, slag, mountain mud, silt, etc. to produce provisions cross-section of ordinary solid bricks, hollow bricks, and other products.

Vacuum extruder clay brick making machine use the raw materials.

Vacuum extruder clay brick making machine produce different bricks like clay solid bricks and clay hollow bricks.

Baoshen clay brick making machine company

Baoshen clay brick making machine series products have more than 40 varieties and over 100 specifications.our brick making machine have been exported to countries such as Kazakhstan,Uzbekistan,Kyrgrzstan,Tajikistan,Russia,Nepal ,Sudan,South Africa,Uganda,Mongolia,Argentina,Libya,Peru,Venezuela,Bangladesh and india,etc.have won great fame and popularity.

Production Strength:

Vacuum extruder clay brick making machine

Advantage:

Vacuum extruder clay brick making machine main body is made from cast iron,main shaft and bearings one-time processing,good stability and long life service.

1)harden surface gear of Vacuum extruder clay brick making machine was adopted in reducer, clutch are a component with own patent,without any shaking during working, even the extruder can working normal without foundation bolts.

2)the steel material of shafts and gears in Vacuum extruder clay brick making machine are adopt high quality carbon steel and alloy steel, the key parts are quenched and tempered treated so as to extend fly ash bricks making machine life.

3)The spiral cut reamer of Automatic Vacuum extruder clay brick making machine adopt wear-resistance metal spray painting technology; The upper stage mixing shaft, the cut reamer big shaft, the up-down body etc. are all passed the aging, quenching and tempering process.

4) Vacuum extruder clay brick making machine features with simple and compact structure, reasonable design, strong applicabilty, lower energy consumption, and high efficiency. the equipment can work steadily without installing of foundation bolts.

1. Technical specification

Vacuum extruder clay brick makig machine

|

Model

|

JKB

|

|

Production capacity (pieces/h)

|

10,000~20,000 pieces (standard brick)

|

|

Extrusion pressure (Mpa)

|

≥3.0

|

|

Required power (KW)

|

Upper stage: Y280M-6-45

|

|

Lower stage: Y315M-6-90

|

|

Vacuum pressure

|

≥-0.092

|

|

Main shaft speed (rpm)

|

Upper stage: 38rpm

|

|

Lower stage: 25rpm

|

|

Shaping moisture content (wet basis %)

|

16 ~ 20

|

|

Raw material plasticity index

|

7 ~ 15

|

|

Required reducer

|

Upper stage: ZLY600D i=10.89

|

|

Lower stage: ZLY960B i=15.95

|

|

Required V-belt

|

Upper stage: 7-SPB-4700

|

|

|

Low stage: 9-SPC-5500

|

|

Required vacuum pump (water circulation type)

|

2SK ~ 6 ~ 2SK-12

|

|

Required electric motor

|

Y15 ~ 22KW

|

|

Overall dimension mm length × width × height

|

5,300×5,550×2,510

|

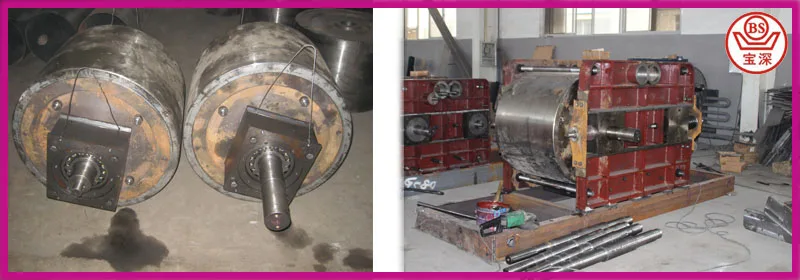

2.spare parts for good quality Vacuum extruder clay brick making machine

baoshen good quality clay brick machinery company not only provides customer with various fully automatic Vacuum extruder clay brick making machine,but also provides services like brick making process design of solid brick &hollow brick,brick kiln design and build,brick dryer design and build,brick factory turn key project contract.

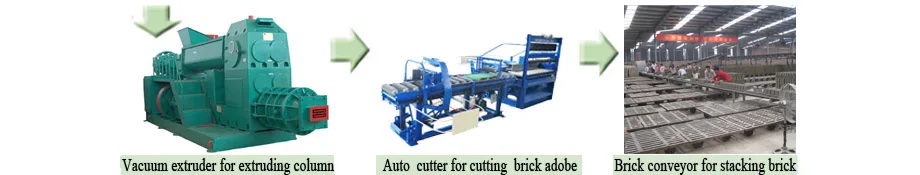

clay brick production line:

Vacuum extruder clay brick making machine ,clay brick production line

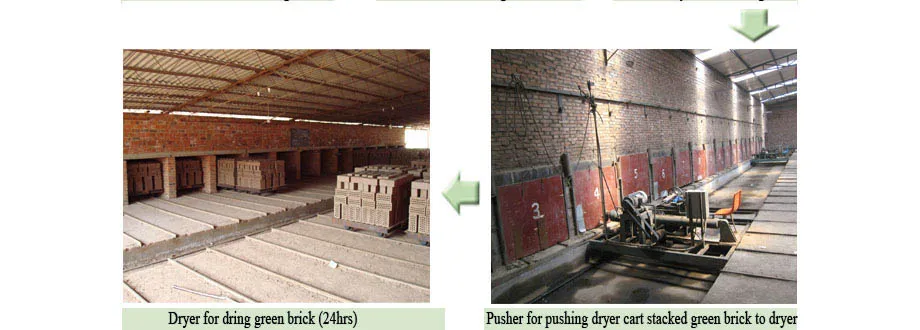

The brick factory including fully automatic clay brick making machine for shaping, brick dryer(small tunnel dryer & chamber dryer) for drying and brick kiln (hoffman kiln&tunnel kiln)for firing.

Good quality autmatic Brick making machine , Vacuum extruder clay Brick making machine including:

|

No.

|

clay brick making machine

|

|

1

|

Box feeder

|

|

2

|

Belt conveyor

|

|

3

|

Primary roll crusher

|

|

4

|

Belt conveyor

|

|

5

|

Double shaft mixer

|

|

6

|

Belt conveyor

|

|

7

|

High speed roll crusher

|

|

8

|

Belt conveyor

|

|

9

|

Double shaft mixer

|

|

10

|

Belt conveyor

|

|

11

|

Double stage de-airing extruder

|

|

12

|

Vacuum pump

|

|

13

|

Air compressor

|

|

14

|

Auto brick cutting system

|

|

15

|

Belt conveyor (waste brick return to mixer)

|

|

16

|

Control panels

|

|

17

|

V Belt

|

|

18

|

Spare parts

|

|

19

|

dryer

|

|

20

|

kiln

|

clay brick making process

Vacuum extruder clay brick making machine for brick making process,including many different clay brick machinery.

1.taking clay with box feeder ,belt conveyor carry clay to roller crusher to crush under 5 mm.

2.crushing clay under 5 mm, belt conveyor carry clay to double shaft mixer to mix clay.and then use fineness roller crusher to crush clay under 3 mm.

3.after fineness roller crusher,the clay is under 3 mm. belt conveyor carry clay to extrusion mixer to mix again,which to enhance the plasticity to make good brick.and then extruding wet column brick with Vacuum extruder clay brick making machine.

4.after extruding wet column brick,cutting column brick under 1.0-1.5 m,use the automatic brick cutter to cut piece brick.with different capacity.

Our company can not only provide various good quality fully automatic Vacuum extruder clay brick making machine, install clay brick machinery,commossioning.but also dprovide services like process design, brick dryer for drying and brick kiln (hoffman kiln&tunnel kiln)for firing.

Newest clay brick making factory layout:

After sale:

Before-sale services:

(1) tell customer how to build new brick factory, including clay brick making machine, drying and firing.(Confirm clay,power electricity,water,land area, fund)

(2) Guide customers to choose the best and economic plant, recover the investment within short time.

(3) site inspection

(4) provide the offer, flow chart, and detail specification of each clay brick making machine.

In-Sale services:

(1)Quality of clay brick making machine control must be inspected strictly

(2)In accordance with the agreements stipulated in the contract

After-sale services:

(1) We will send the technicians about clay brick making machine to guide with device installation, debugging and training operators until customers are fully satisfied.

(2) Guarantee for brick machine, materials and equipment supplied under this quotation are valid for a period of 12 months after commissioning or 16 months after delivery whichever is earlier. Warranty shall cover manufacturing defect in material and workmanship but exclude:1. Daily wear and tear 2.mishandling or improper operation3. Incoming power supply fluctuation 4. Consumable and spare parts.

(3) Regular visit customer, consult with the customer feedback, come true with the customer's two-way communication Fired Fully Automatic Clay Bricks and Blocks Machinery.

video

http://www.CHINA-BAOSHE.COM

http://www.youtube.com/watch?v=s7l3YJ_uSzI&feature=relmfu